The Potential of SAP S/4HANA for Your Logistics

More than just an upgrade

The upcoming migration from SAP ERP to SAP S/4HANA presents German companies with a strategic change of course that goes far beyond a routine software update. The end of maintenance for SAP Business Suite 7 on December 31, 2027 not only creates time pressure to act, but also the opportunity for a fundamental realignment of the entire supply chain architecture.

While a Gartner study shows that after almost ten years of availability, only 39% of ECC customers have licensed S/4HANA and 61% of German companies are still undecided, reluctant organizations are missing the opportunity to transform their supply chain into a strategic competitive advantage. SAP S/4HANA is not the legal successor to the old Business Suite, but a new product developed from the ground up specifically to meet the requirements of modern, networked Supply Chains is tailored.

SAP S/4HANA for Your Logistics: The Most Important Facts at a Glance

- Time pressure due to end of maintenance: SAP Business Suite 7 will lose standard support on December 31, 2027 – 61% of German companies are still undecided

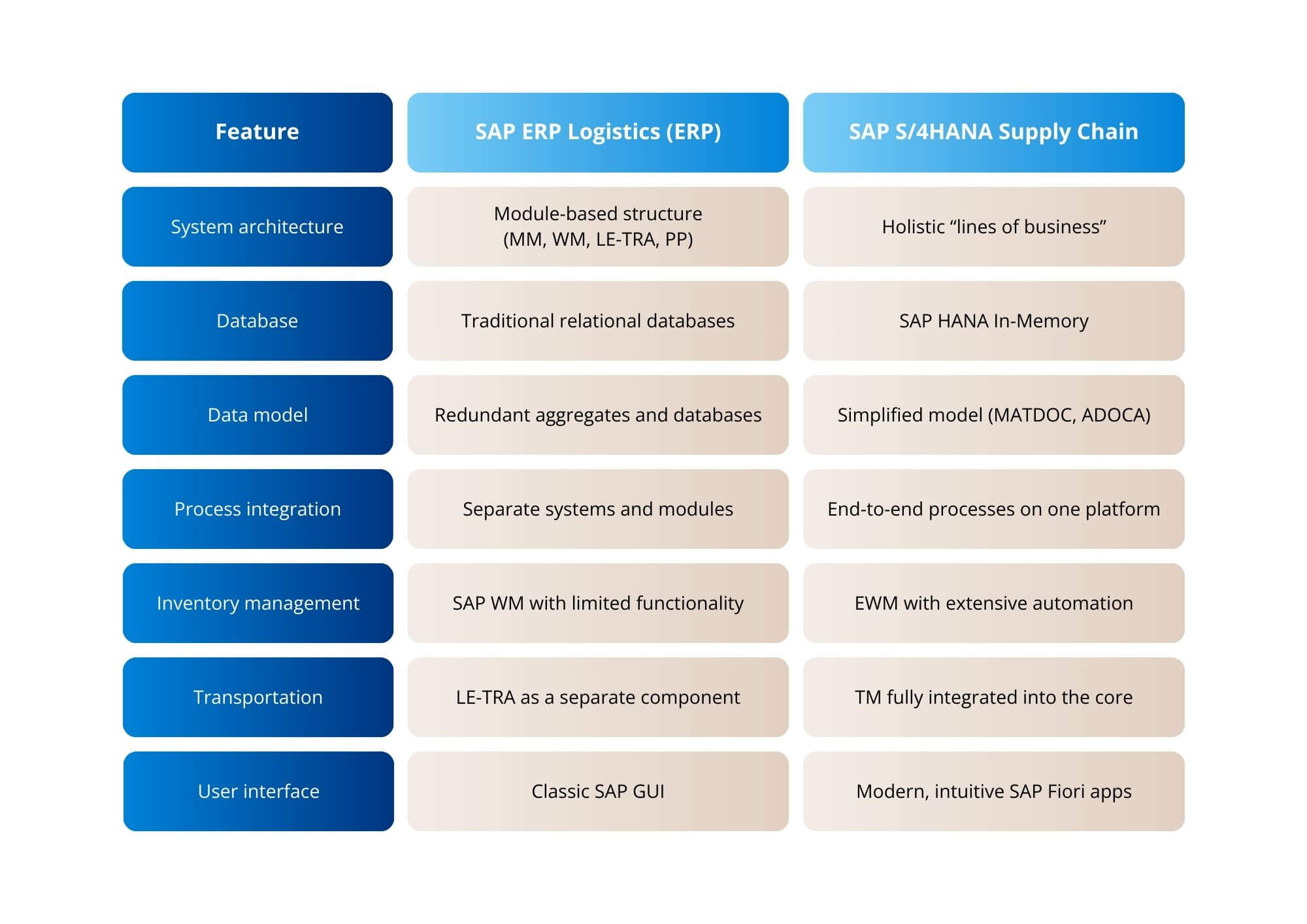

- Supply chain revolution: Transition from functional silos (MM, WM, LE-TRA) to holistic "lines of business" for end-to-end processes

- Operational excellence: Intelligent automation, AI-supported process optimization and end-to-end transparency throughout the entire supply chain

- Modern logistics solutions: EWM as WM successor, integrated transportation management and simplified data model with "single source of truth"

- Practice-proven implementation: Josera demonstrates successful integration of SAP core with cloud solutions for operational process optimization

The Technological Foundation: More than Just Database Technology

Modern system architecture for operational excellence

A fundamentally revised system architecture based on the SAP HANA database is at the heart of SAP S/4HANA. This technological foundation enables one thing above all: the seamless integration and automation of logistics processes in real time.

The real added value lies not in pure speed gains, but in the new processes that are made possible as a result: AI-supported demand forecasts can flow directly into scheduling, inventory optimization is automated based on current consumption data, and bottlenecks in the supply chain are proactively identified before they lead to delivery problems.

Simplified data model: The "single source of truth"

One of the most significant innovations in SAP S/4HANA is the drastic simplification of the data model. In the past, data in SAP ERP was often stored in redundant and complex table structures, which not only impaired performance, but above all made cross-system process automation more difficult.

S/4HANA eliminates these redundancies by merging them into new, leaner tables. Examples of this simplification include MATDOC for inventory management, which replaces over 26 old tables from SAP ECC, and ACDOCA ("Universal Journal"), which combines data from FI, CO, AA, and ML as a central table for financial accounting and controlling.

This data model simplification creates a "single source of truth" that enables a consistent view of all supply chain processes. It not only significantly reduces storage requirements, but also improves data quality and enables seamless, cross-system collaboration – a prerequisite for end-to-end automation from supplier to customer.

The Supply Chain Revolution: From Silos to End-to-End Processes

Paradigm shift in the system architecture

The migration to SAP S/4HANA means a fundamental change from the module-based structure of the old SAP ERP platform with discrete, often isolated modules such as Materials Management (MM), Warehouse Management (WM) and Logistics Execution - Transportation (LE-TRA) to holistic "Lines of Business" (LoBs).

This transition is the philosophical core of the thesis that this is more than just an upgrade. Instead of mapping functional silos, the new architecture focuses on seamless end-to-end processes across all business units. The LoB "Supply Chain", for example, no longer integrates warehousing as an isolated unit; it also includes production planning, batch traceability, inventory management, and transportation logistics in an end-to-end process flow.

Sourcing & Procurement: Intelligent procurement in real time

The "Sourcing and Procurement" area includes functionalities such as automated purchase requisitions, operational procurement, and supplier management. Companies benefit from end-to-end transparency in their supplier spend and can further optimize procurement processes through integration with cloud solutions such as SAP Ariba.

Transparency about supplier performance and risks enables proactive decisions on supplier diversification and risk minimization - a decisive advantage in volatile global markets and complex supply chain networks.

Extended Warehouse Management (EWM): The future of warehouse logistics

EWM is the central pillar of modern warehouse logistics in SAP S/4HANA and replaces the outdated SAP WM. It offers high scalability for warehouses of any size and automation level and enables deep integration of material flow systems, robotics, and automated guided vehicles (AGVs).

The solution supports advanced strategies, such as wave and cluster picking, and provides continuous visibility of stock levels and processes. For highly automated warehouses, EWM can be operated as a decentralized system, while the embedded EWM is ideal for manual warehouses.

Transportation Management (TM): Seamless transportation integration

The TM functionality, which existed in SAP ERP as a standalone solution (LE-TRA), is now fully integrated into the S/4HANA core. This enables seamless connections to supply chain and financial processes without media disruptions.

The core functions include intelligent route and tour planning that takes into account costs, time, and priority; automated carrier selection; freight cost accounting; and continuous shipment tracking. This integration eliminates manual interfaces and significantly reduces sources of error.

Practical Example: Josera’s Digital Yard Transformation

The initial situation: Manual processes as a brake on efficiency

The Josera case study illustrates impressively how S/4HANA'sresulted in potential can be exploited in practice. The company was faced with the challenge of optimizing its internal plant logistics.

The manual vehicle-handling process and the lack of transparency on the factory premises resulted in costly waiting times for suppliers and freight forwarders. The main logistical challenge was to make the processes from truck check-in to ramp allocation and check-out digital and transparent.

The integrated solution: SAP core plus specialized cloud services

The chosen solution was an intelligent integration of the SAP S/4HANA core with a specialized, cloud-based software: platbricks® Yard Management. This approach exemplifies the concept of "two-speed IT": the stable SAP S/4HANA core serves as the backbone for fundamental business processes, while the agile, cloud-native solution covers the specific and fast-paced logistical requirements of yard management.

The SaaS platform integrates seamlessly into the SAP ERP and warehouse management system via standardized interfaces. The solution digitalizes all yard processes: from appointment booking for truck drivers and a self-service portal to parking space management and the automated allocation of ramps.

Measurable success through operational process optimization

The implementation led to several quantifiable benefits through the optimization of operational processes with SAP:

- Higher ramp utilization: Thanks to pre-booked, coordinated time slots, ramp utilization can be increased and idle time avoided.

- Continuous transparency: The continuous status display of vehicles and loading processes provided the management with an overview of the overall situation on the site at all times.

- Cost reduction: Systematic vehicle registration and the elimination of waiting times reduced downtime costs and unnecessary personnel expenses for administrative tasks.

- Automated processes: Digital truck dispatch reduced the need for personnel at the factory gate and made communication easier, even with different languages.

The Josera case study proves that SAP S/4HANA is not a rigid, monolithic solution, but an open platform that can be extended with specialized cloud services to solve specific business challenges in the supply chain.

Understanding and Overcoming Migration Challenges

Why German companies are still hesitating

Despite the clear benefits and the impending end of maintenance, a significant proportion of companies are still hesitant to make the switch. This reluctance is due to key barriers:

- Complexity and budget risks: Migration projects are perceived as costly, complex, and expensive, with the risk of budget overruns and delays.

- Custom Code (Z-Code) Management: The customer-specific code developed over decades is often not compatible with S/4HANA and is difficult to evaluate due to a lack of documentation. A common mistake is to simply transfer this code into the new system, which increases complexity and costs without using process simplification.

- Skills shortage: There is a lack of qualified, S/4HANA-experienced consultants and internal employees, which leads to increased costs and quality problems during implementation.

Inadequate change management: Without early involvement and training of employees, acceptance of the new system can remain low, which can cause technology investments to fail.

Choosing the right migration scenario

The strategic decision for the right migration approach is critical to success. Three main scenarios are available:

- Greenfield approach: Complete reimplementation from scratch, ideal for companies seeking radical business transformation and complete elimination of technological legacy.

- Brownfield approach: Conversion of the existing SAP ERP system, more cost-effective and faster, as historical data and settings are transferred. The disadvantage lies in the transfer of technical legacy data.

- Selective Data Transition (Bluefield): Hybrid approach that combines the advantages of both scenarios and enables the selective transfer of relevant business data and the consolidation of several individual systems.

Strategic Recommendations for Managers

Early and holistic planning

The migration should be seen as a comprehensive supply chain transformation, not just an IT project. Start with a readiness assessment phase to scan the current system, identify potential obstacles, and create a realistic implementation plan.

Strategic custom code management

Follow the strategy of not blindly adopting custom code, but rather strategically evaluating and cleaning it up. The goal is a "clean core", freed from unnecessary, redundant, or outdated adaptations. Automation tools can automate 70-80% of code customizations.

Change management as a success factor

Involve users in the process early and provide comprehensive training. The new, intuitive SAP Fiori user interface can be an important lever for increasing user acceptance and productivity.

Using partnerships strategically

Work with experienced implementation partners who have proven methodologies and S/4HANA expertise. External consulting closes knowledge gaps and significantly accelerates the transformation.

The migration to SAP S/4HANA is an inevitable but also rewarding transformation. It is the catalyst for a profound redesign of supply chain processes, enabling companies to turn their supply chain into a strategic competitive advantage.

Conclusion: Seize the Opportunity for Transformation

SAP S/4HANA is much more than a technical upgrade - it is the transformation of your supply chain into a strategic competitive advantage. The end of maintenance in 2027 is not just a system change, but an opportunity to redesign: from isolated modules to integrated end-to-end processes, from manual control to AI-supported automation. Practical examples, such as Josera, demonstrate how integrating the SAP core with specialized cloud solutions enables operational excellence. The right migration strategy and experienced partners make the difference between a compulsory exercise and an investment in the future.

Written by