Process Mining: The Future of Process Optimization

Successfully and sustainably optimize business processes

Process Mining: The Key to Successful Digitization and Automation of Business Processes

Did you know that, according to IDG Research Services, more than 90 percent of companies in Germany see process mining as a crucial lever for digitization?

Why? Quite simple: Process Mining goes beyond classical Process Management, the so-called BPM (Business Process Management). BPM provides a holistic overview of business processes. In contrast, Process Mining deepens into individual processes and details. Only when companies have gained a detailed insight into existing individual processes can they implement solutions for optimization and, for example, create an error-free basis for automated technologies. The created transparency facilitates digitization, also in the form of Robotic Process Automation (RPA).

Arvato Systems is your competent partner for all aspects of optimizing your business processes: Together, we pave your way to the successful implementation of process mining. Benefit from the advantages of this innovative technology.

Process Mining: BPM next Level

Process Mining is a Process Management technique that allows companies to optimize individual processes sustainably through fully automated preparation.

Unlike conventional Process Management methods, Process Mining also analyzes previously unexplored regions of your process landscape. The decisive advantage of Process Mining: With the help of the technology, extreme cases, outliers, loops, and inefficiencies are identified in individual process flows that were previously lost or left unexplained in statistically averaged KPIs.

Think of Process Mining as a kind of x-ray of real-world process data that captures a large number of process variations. Process mining helps your organization, regardless of your industry, gain complete visibility into operational processes. This enables you to identify deviations from the intended processes and to develop suitable measures for optimization. You can continuously monitor whether your measures are effective and react quickly to changes by improving them.

Among the classic users of the technology are primarily large and medium-sized companies from a wide range of industries. Especially in companies' digitization strategies, Process Mining is a key technology for their success.

The Process Mining Technology Can

You too can benefit: these are the advantages of process mining for your company

The overarching goal of the data-based evaluation of digital traces is to sustainably improve processes in the operational area of the company. The method is particularly useful when conventional techniques do not allow a formal description of the process due to a lack of suitable data.

You can find out what your real processes look like and how you can benefit from them in our Process Mining workshop.

The advantages of process mining at a glance:

- Reduce business costs in the long term by identifying and eliminating weaknesses and bottlenecks in process steps

- Understand and optimize key parameters of business processes

- Eliminate subjective opinions and assumptions and replace them with fact-based findings

- Creating a sound, data-based foundation for decision-making processes

SAP is one of the most important and well-known systems for internal company processes. With BIC Process Mining for SAP, it is now also possible to measure and monitor processes using real data from the SAP system. This solution provides already preconfigured end-2-end processes such as order-to-cash or procure-to-pay, enabling easy operation with little integration effort. BIC Process Mining for SAP identifies weak points in processes and thus contributes to Process Optimization.

Process Mining: An Example for Sustainable Process Optimization

The basic idea of Process Mining can best be illustrated with a practical example:

Due to frequent complaints on the phone, a renowned supplier of custom-made bicycles found out that the promised delivery times had repeatedly not been kept for several months. An exact analysis had to be carried out as the responsible persons could not explain why this was the case.

The first end-to-end review based on the processes modeled in BPM - from ordering to delivery - did not show any abnormalities. The processes of the respective departments involved had always been completed within the specified time frame.

The processes had to be examined more thoroughly, which led to the use of Process Mining software. The order-to-cash process from the SAP system served as the data basis. With the Process Mining tool, it was possible to separate the data of the slow process instances from the normal ones and compare them in a process simulation. This revealed a significant deviation in the lead time between completion of the frame and installing the suspension fork. When further focussing within the Process Mining Tool, it turned out that the delay, regardless of the type of bicycle frame, only occurred with purchased suspension forks from a recently added manufacturer. The analysis of the affected order process revealed that the automatic order confirmation did not arrive immediately but always on Mondays, contrary to expectations. This clearly indicated a problem in the IT interface.

With this information, the IT department quickly identified the actual problem - an incorrectly configured batch run. Instead of directly triggering the order, the orders were first collected and sent on Monday. This delayed the delivery of the suspension fork and, therefore, the assembly, which ultimately delayed the delivery to the customer.

Our conclusion: By analyzing the causal chain with Process Mining, the problem could be narrowed down, found, and solved quickly. The delivery dates were met again. As a further measure from the lessons learned, the IT interfaces were assigned to the business processes so that deviations from the target can be seen more quickly in the future.

Application in Practice: How Process Mining Works

The concrete deployment of Process Mining methods in practice always depends on the technical status of the company. In the following, we explain how you can deploy Process Mining in practice step by step:

-

Step 1: Define the Processes

Which processes should be analysed?

The first step is to define specific business processes for further analysis. It is recommended to prioritize processes with obvious weaknesses and potentials. An example: The KPIs of a medium-sized company indicate that invoices are paid late and negotiated discounts are not taken advantage of as a result. In this case, it is of course useful to look at the order-to-cash process from SAP and analyze the release and posting of invoices in a targeted manner.

-

Step 2: Creating the Data Basis

The data basis

The basis for every Process Mining tool is the existing database. Many companies do not even know to what extent they collect data digitally in their business processes. For example, invoices in the purchasing department are often received by post and processed manually - but in the end the data is usually stored in a tool such as SAP and is thus available for digital evaluation. The second step is therefore to collect the data basis for the business process to be analyzed, with support from Arvato Systems. Especially in the complex SAP environment we provide so-called extractors and connectors to the Process Mining tool through our SAP expertise, so that a data basis can be easily extracted for later analysis.

-

Step 3: Generate the Visual Processes

Read in data and create processes

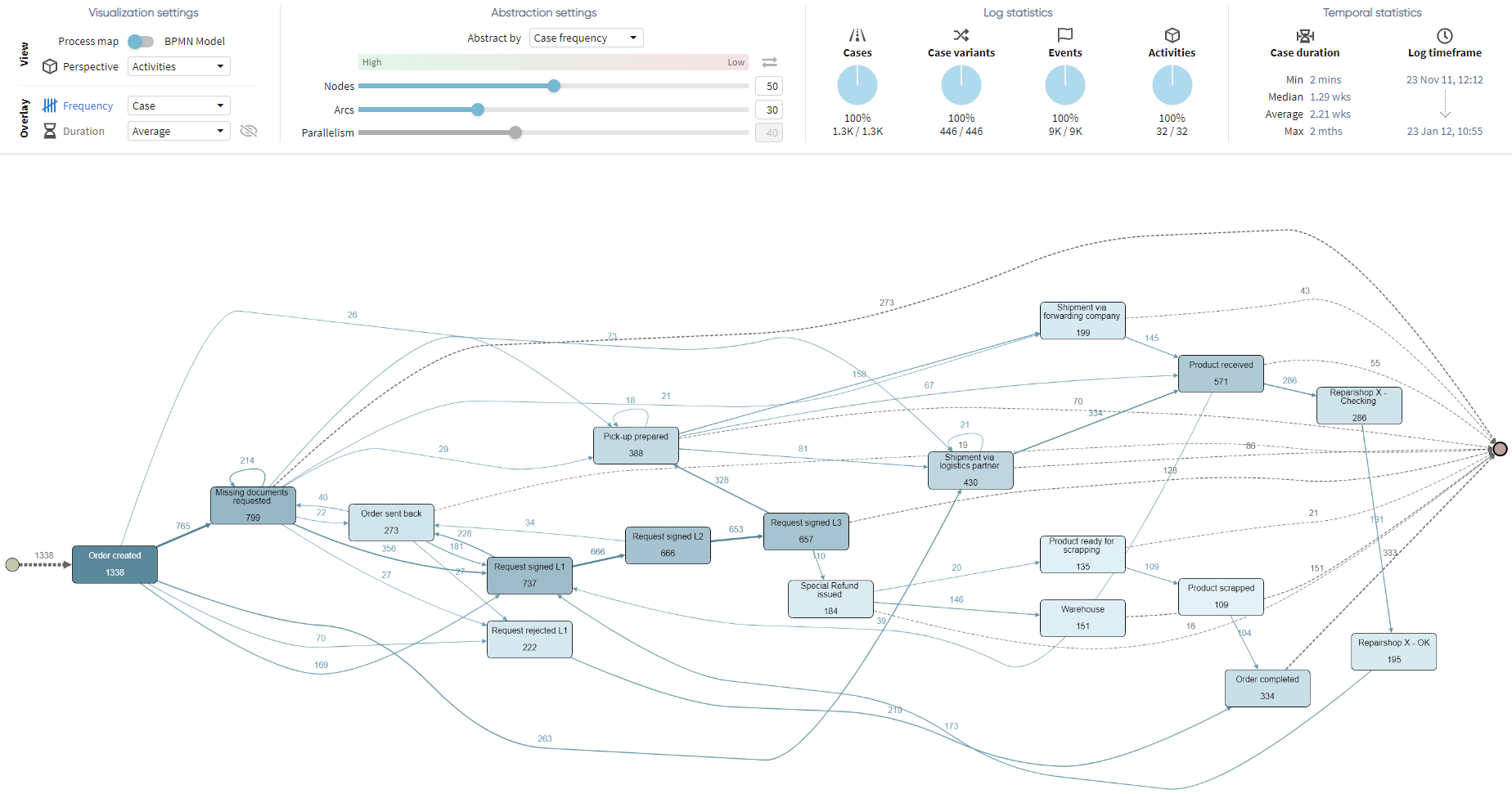

In this step, the visualization of the business processes takes place. The software imports the existing database recognizes the coherence, and visualizes the process data in a model. A representation of this scope, which the software achieves in a few seconds, can hardly be realized with conventional methods.

Tip: If your company is not yet experienced in Process Mining, individual or several steps can be outsourced to an external service provider (outsourcing).

-

Step 4: Analyzing the Processes

Analysis of causes

In the fourth step - the analysis of causes - you will also be supported by the software. The program, for example, displays loops, bottlenecks, and outliers in a targeted manner. Different process views, focusing on the duration or number of cases, allow you to find the right perspective quickly. With the numerous filter and analysis options, you can now limit the displayed process to specific time periods, customers and industries, or even resources. The filtered data can easily be stored as a separate process and compared with each other, for example, in a process simulation. An optimized target model can also be created or uploaded directly, which can be compared with the actual model collected in step 3.

-

Step 5: Define and Implement the Measures

Derive optimisation measures

In the fifth and final step, the process knowledge gained is used to derive and implement suitable measures for optimization. At this point, it is important to check the effectiveness of the measures subsequently continuously and to optimize the measures themselves if necessary.

The Prerequisites for Using Process Mining Successfully

Every Process Mining software works according to the same principle in its basic function. It brings process activities into a logical sequence through a timestamp and assigns them to the process instances. The processes can also be enriched with further attributes, such as customers, industries, resources, etc.

This means that the IT systems and databases used must record these log data. Typical source systems for Process Mining include systems such as Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), or Supply Chain Management (SCM).

A Glimpse Into the Future: Big Data and Digitization

Unstoppable forward: The digitalization of business processes will continue to advance in the future and fundamentally change the way we work. We are convinced that data-based analytics methods, Process Mining, and Process Automation will be key technologies for companies' digitization strategies.

The trend towards digital processes and Big Data technologies represents an important success factor for companies in all industries to continuously improve their own business model. Process Mining is ideally suited to present Big Data in clearly visualized processes and thus allows the precise reconstruction of business processes in a dimension never seen before.

We at Arvato Systems would like to accompany you on this path and support your company efficiently in the optimal transformation of processes and IT.

Frequently Asked Questions About Process Mining

-

What is Process Mining?

Process mining is a method for the systematic analysis and evaluation of business processes. With the help of this technique, important data is stored, processes are illuminated in detail and details of various business processes are displayed. Process mining visualizes individual footprints to your traceable processes - even from previously unexplored areas of your process landscape. This allows companies to identify subtle problem areas within process flows, evaluate them and react based on appropriate measures.

-

For which companies is Process Mining important?

Process Mining is essential for medium-sized and larger companies, but also for small, highly digitalized companies from different sectors. It is a decisive key technology for the success of a company, especially when it comes to developing or optimizing digitization strategies.

-

What are the goals of Process Mining?

Process Mining pursues the fully comprehensive and detailed visualization of individual footprints to traceable processes in the first step. As a result, it is possible to analyze and evaluate the process steps. The technology identifies bottlenecks as well as redundant or repetitive process flows. Process Mining optimizes company-internal processes through targeted measures, reduces throughput times, and increases the efficiency of your processes.

-

What are the benefits of Process Mining for companies?

Process Mining documents and visualizes internal company processes. This makes it possible to compare ACTUAL and TARGET states, make data-based decisions or identify patterns, anomalies, and their causes. On this basis, companies can continuously optimize their processes.

-

How does the Process Mining process work?

Process Mining collects the digital data of any process flow of a company to visualize and analyze it. Using process models, filters, dashboards, and simulations, all steps of a process can be traced in detail. Process Mining provides insights into every process level and identifies bottlenecks, deviations and inefficiencies. At the same time, the technology creates optimization potential.

Your Contacts for Business Process Optimization