SAP Asset Intelligence Network (SAP AIN)

Features and Benefits for Maintenance

Today, many companies map their business processes with the help of SAP. Often, only the value-adding processes along the logistics chain are considered, which are primarily found in the areas of procurement, sales, and production. But for manufacturing companies, in particular, the necessary machines and equipment must be available in an increasingly efficient and tightly scheduled production - which also has to react very flexibly to changes at short notice.

In addition, maintenance, servicing, and inspections must be carried out according to correct specifications and at regular intervals to identify weak points in machinery and equipment. A consistent view of the composition of technical objects and any spare parts is essential both internally and in the event of possible callbacks.

Here, the SAP AIN software solution supports corresponding customers in efficiently managing their information on assets and fully exploiting the benefits within the framework of Industry 4.0 and the spread of IoT.

How Does SAP AIN Fit Into Enterprise Asset Management?

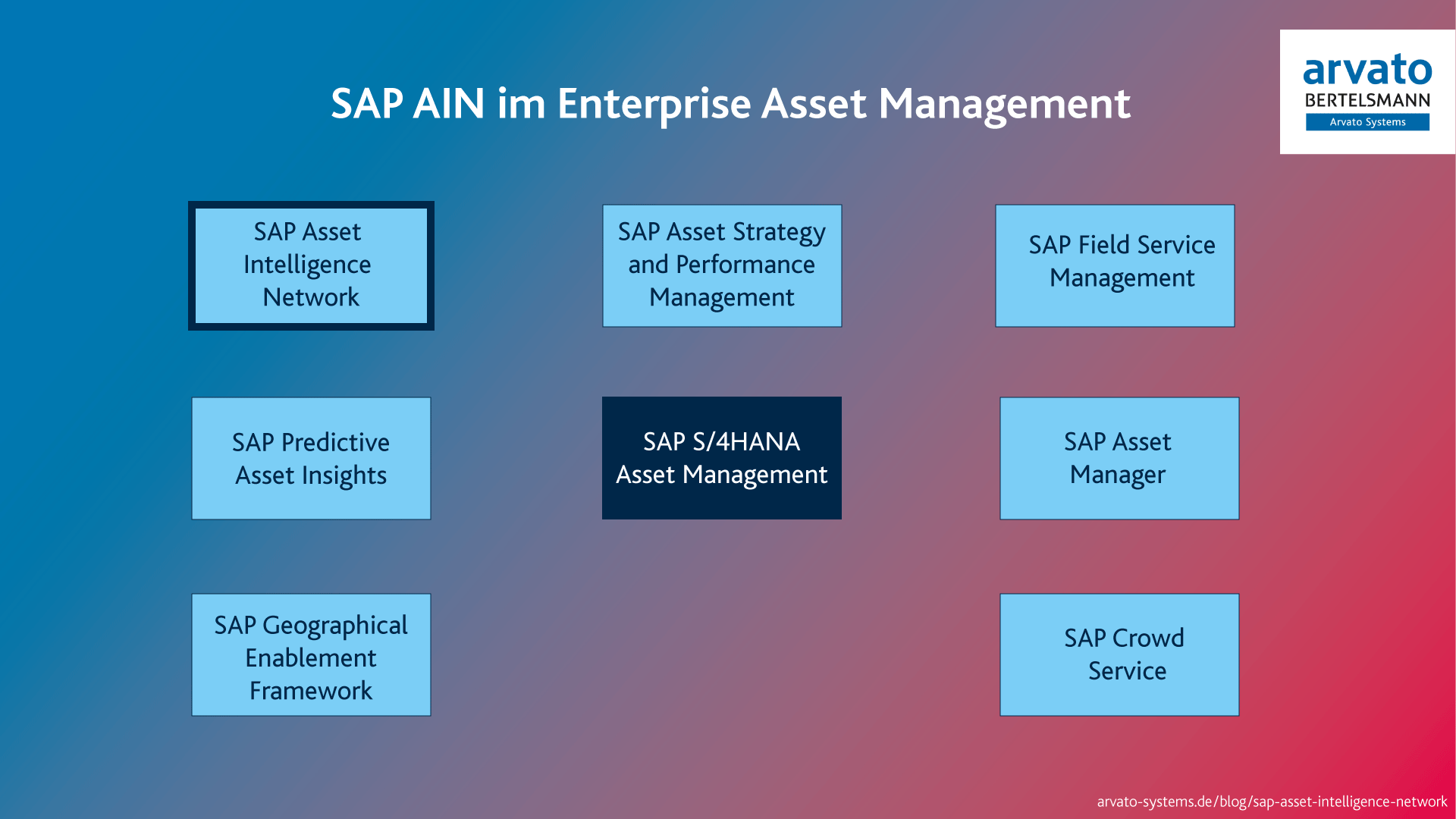

The SAP Asset Intelligence Network (SAP AIN) is part of the strategic offensive of new SAP products in Enterprise Asset Management (EAM). SAP AIN aims to connect manufacturers, operators, and service providers of technical equipment and machinery and create a common collaboration platform.

In addition to SAP AIN, there are other SAP solutions for a holistic view of the lifecycle of technical assets and their operational support, which focus more on supporting field service employees, analyzing economic and technological KPIs, or IoT-supported prevention of asset failures, for example.

Which Tasks Does SAP AIN Support in Maintenance and Repair?

In the context of the management of technical plants and equipment, a problem of data integrity often arises, particularly in the case of a large number of objects, which becomes more relevant as the life cycle progresses but also represents a significant factor at the beginning. When plants or equipment are procured and put into operation, the essential information in the form of

- parts lists

- spare parts

- technical descriptions

- maintenance instructions

- and other technical details

usually have to be maintained in the system to provide the basis for subsequent operational support and tracking. Such information is often requested from the manufacturer by the plant manager, for example, and then manually extracted into the system. This can lead to initial discrepancies in terms of data quality and completeness. On the other hand, such manual data entry also ties up considerable employee resources for processes that do not add value, which should be avoided.

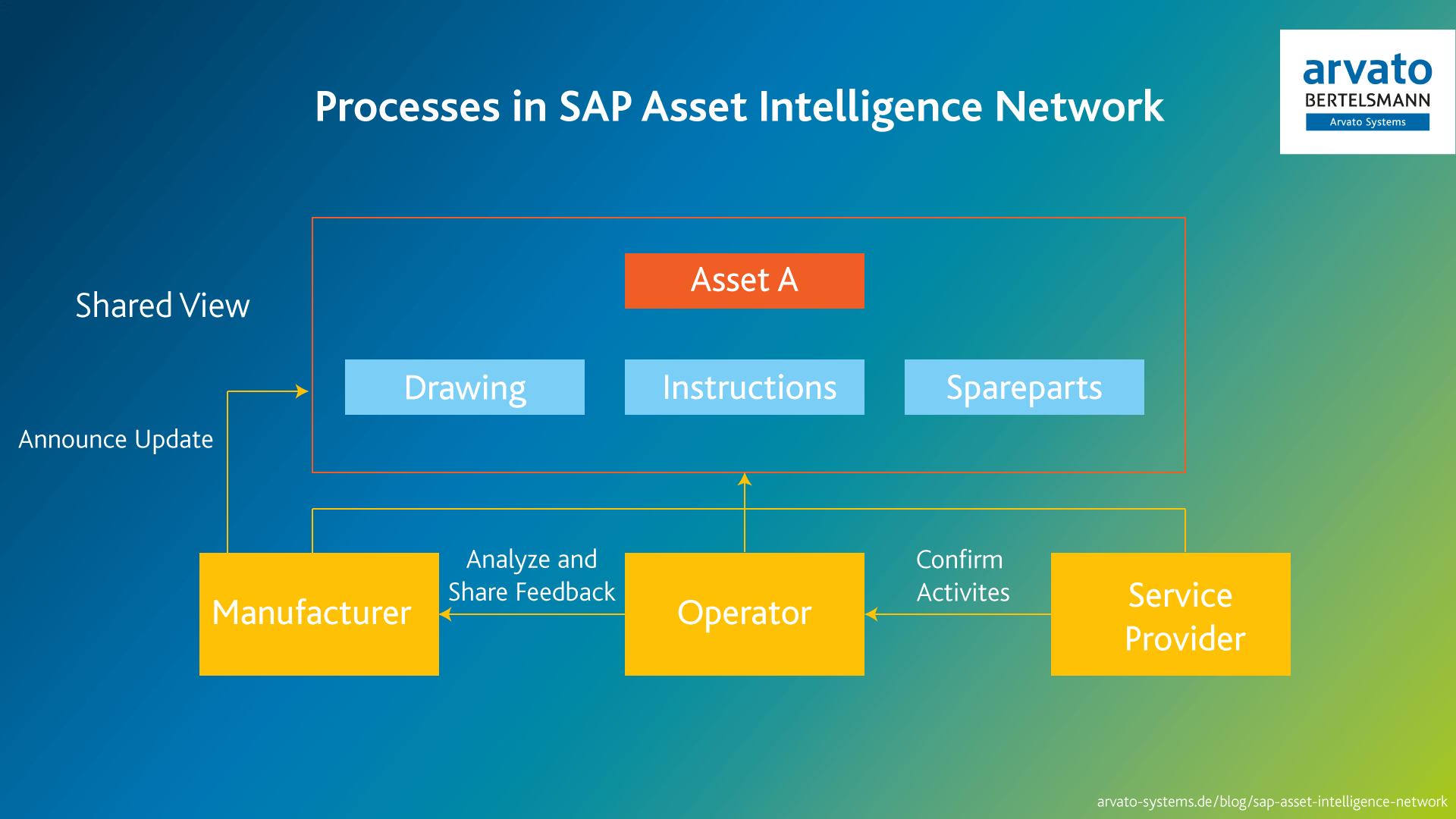

At this point, SAP AIN intends to create a central database that allows manufacturers, plant operators, and plant supervisors to have access to the same information and to integrate it into their processes. This means as it were, that a large part of manual activities for generating master data and associated documents are eliminated with the use of the tool. By working on the same database and partially sharing information regarding technical objects used, direct information can also be transferred from the manufacturer to the plant operator via announcements - for example, if there are changes to the specified maintenance schedules or new firmware is available for a plant.

In addition, in the sense of a continuous improvement process, it is possible to communicate suggestions for improvements to technical objects both internally and externally, which can lead the OEM to make product-specific design adjustments.

How Is the SAP AIN Integrated and Are There Extensions That Can Be Made?

As part of Enterprise Asset Management, SAP AIN is seamlessly integrated with all its other solutions, increasing transparency and simplifying connectivity. Concerning the integration into the legacy system, both a close interlocking to the core processes from maintenance in SAP ERP and SAP S/4HANA can be achieved.

In addition, integrations for harmonizing different company ERP systems are also possible to increase data consistency and integrity. From a technical point of view, the SAP AIN is connected via the SAP BTP so that it is possible to call up all AIN-specific applications from supported mobile devices and web browsers. Suppose the existing applications or delivered information on objects is insufficient in individual cases. In that case, object-specific information can be added, or the user can develop their applications in the cloud, which can then be accessed in the SAP AIN. Concerning the integration of documents, these can be realized either via synchronization with the SAP document management system (DMS) or entirely autonomously in the SAP AIN itself.

Although the SAP AIN is intended to serve as a single source of truth for asset-specific data and to promote strong collaboration between the various parties involved by providing a standard view of this data, the SAP AIN naturally also has an authorization concept. This can be customized to avoid sharing internal information that is subject to a certain degree of sensitivity. Service providers and OEMs can be connected via defined onboarding scenarios, whereby the scope of functions may differ depending on whether service providers and OEMs also own exclusive premium licenses for SAP AIN or only operate with a freemium permit generated by inviting an SAP AIN premium license owner.

Conclusion: Who Can Benefit From SAP AIN?

Since SAP AIN is a licensed product for which a fee is charged, specific issues must be considered to evaluate its use, especially in the cost-benefit comparison. The basic rule here is: The more assets a company has in use and the more complex they are to maintain, the greater the business benefit is likely to be. On the other hand, SAP AIN could also be interesting for those customers who have assets in use themselves but have them maintained by external service providers.

SAP AIN offers the most significant benefits when the manufacturer (OEM) is also involved, and the plant operator and plant maintenance provider are based on a shared database. The various collaboration features between the individual players and data integrity, downstream functions such as improvement suggestions, and joint analyses mean that reactive maintenance becomes a reliable and, above all, a preventive process in which administrative effort and downtime are reduced.

This article is part of our new series on SAP's Enterprise Asset Management. Here, we will take a look at various new SAP products and their possible uses as well as the corresponding target groups.

Written by